Iron oxide, barium oxide or strontium oxide

Sintered

Versatile, see data sheet

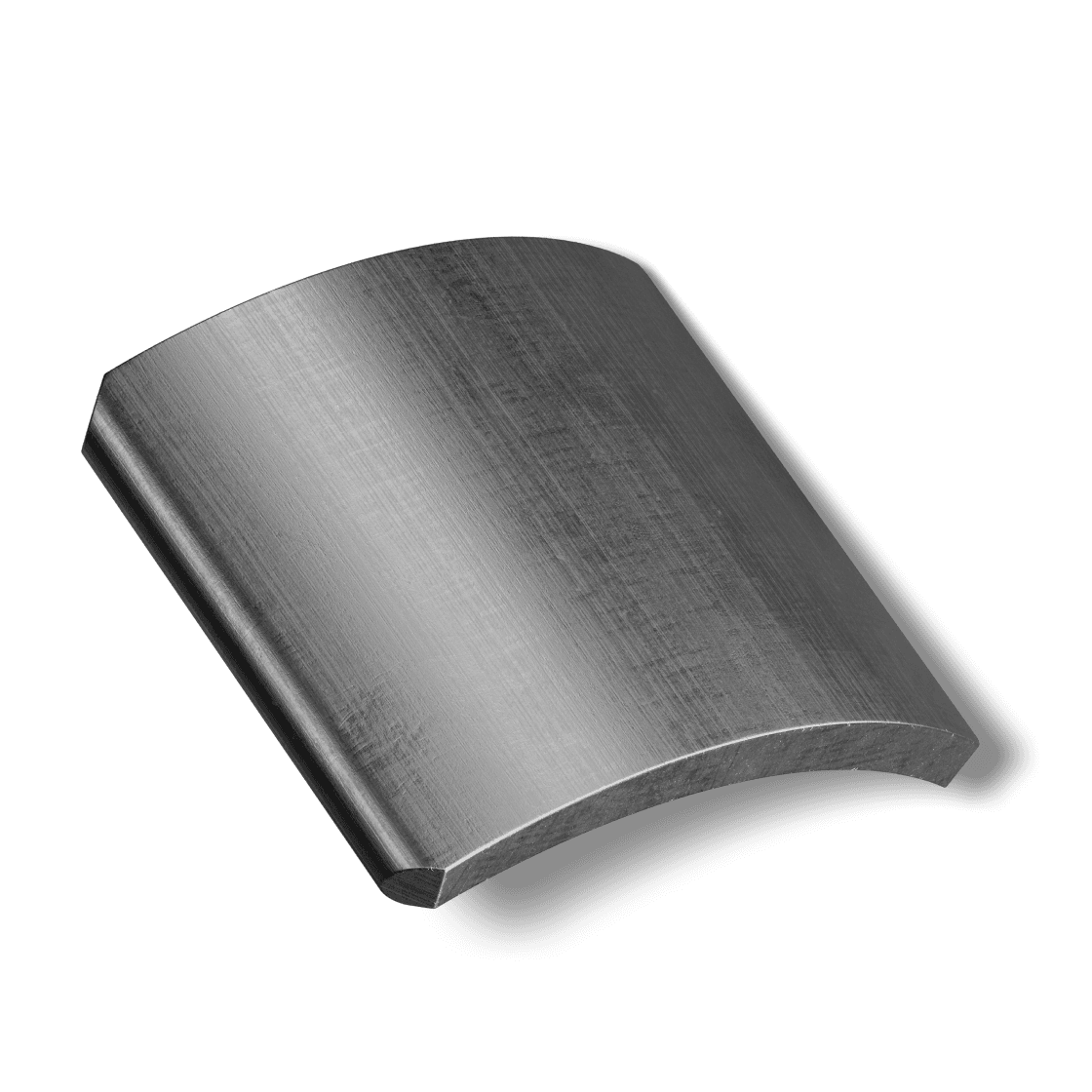

Product

More cost-effective than SE magnets

Although the applications of NdFeB magnets are becoming more comparable, the market share of ferrite magnets remains very high. Ferrite magnets are used in a wide variety of applications, such as speakers, engines and generators. The cost-effective production and the absence of a need for additional coating make them a popular choice.

Cost-effective

Corrosion-resistant

Acid-resistant

General

Special material

Barium and strontium ferrites, in terms of hardness and brittleness, are akin to a ceramic material. They consist of approximately 90% iron oxide (Fe2O3) and about 10% alkaline earth oxide (BaO or SrO). Oxide ceramic is relatively resistant to moisture, solvents, alkalis, weak acids, salts, lubricants and harmful gases. They are shaped by wet or dry pressing, isotropically or in a magnetic field with anisotropic magnets. This gives the magnet a preferred direction and thus achieves a significant improvement in remanence. Smaller magnet geometries are usually produced by dry pressing. To increase the surface density, ferrite ring magnets can be aligned polar anisotropically in the tool.

Chemical Resistance

Largely Resistant

Tartaric acid

Citric acid

Alcohols

Inorganic acids

Gasoline

Conditionally Resistant

Uric acid > 10%

Sulfruric acid diluted

Nitric acid diluted

Citric acid

Ammonia

Not Resistant

Saltpeter

Hydrochloric acid

Acids and alkalis

Sulfuric acid

Fluoric acid

PRODUCTION PROCESS

Sintered hard ferrite magnets

For sintered hard ferrite magnets, the material mixture and the microstructure are crucial. They influence the magnetic properties. The pressing in a magnetic field enables a wide variety of geometries.

NOTE

Hard ferrites, being a ceramic material, are very brittle and hard. Pressing in a magnetic field allows for radial alignment in certain geometries. Material usage can be minimized through compression moulding.

TECHNICAL DATA

What the sintered hard ferrite magnet can do

Hard ferrite magnets are cost-effective, resistant to most liquids and do not require any coating.

Ferrite dry pressed, isotropic

Ferrite dry pressed, anisotropic

Ferrite wet pressed, anisotropic

Further Questions? Talk to an Expert!