Alloy, based optionally on: Fe, FeNi, Co, nanocrystalline (Fe, Si, Cu, Mo, Nb, etc.)

Amorphous, nanocrystalline

Product

It all depends on the alloy

The ribbons are suitable for use in a range of applications, depending on the alloy used. What they all have in common are their excellent magnetic properties. The microstructure of the alloys is amorphous due to the high quench rate. If the ribbon undergoes further temperature treatment, its structure changes into an ordered arrangement of atoms, nanocrystalline.

Application Fields

Transformers

High electrical resistance

Characteristic hardness

Heat- and corrosion-resistant

General

Qualities

The individual strengths and weaknesses of the alloys – Fe-based alloys, FeNi-based alloys, Co-based alloys, nanocrystalline alloys – can be found in the data sheets. Alternatively, our experts will be pleased to provide you with advice.

PRODUCTION PROCESS

Different alloys available

Amorphous and nanocrystalline ribbons and products differ in the materials used and, in the case of the nanocrystalline alloy, also in the production process. Accordingly, the strengths of the individually alloys differ.

Note

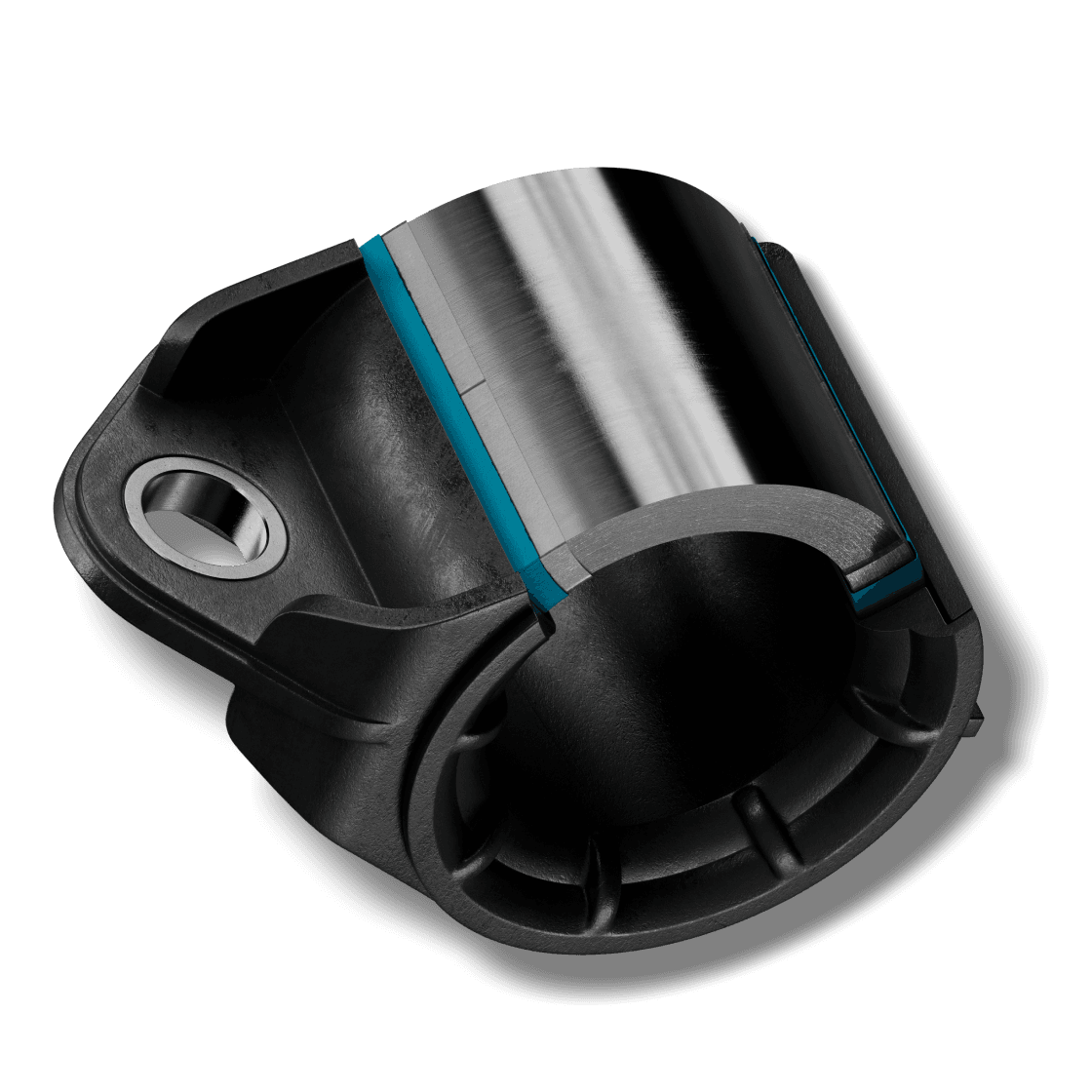

Amorphous and nanocrystalline ribbons and products

Fe-based alloys: Fe, Si, B, C, P, etc. Their outstanding property is their high level of magnetism. Permeability, core losses and other soft magnetic properties are significantly better than those of silicon iron. Additionally, this material is more cost-effective.

FeNi-based alloys: Fe, Ni, Si, B, P, etc. Weaker magnetism, relatively expensive material, but high permeability.

Co-based alloy: Co, Si, B, etc. Lower magnetic properties, but high permeability.

Nanocrystalline alloys: Fe, Si, B, minimal amounts of Cu, Mo, Nb, etc. Cost-effective material with excellent magnetic properties. Even though no expensive Co is mixed in, in certain areas it can have the same outstanding performance as Co-based amorphous alloys.

TECHNICAL DATA

The uses of amorphous and nanocrystalline ribbons

As you can see from the specifications, the properties depend on the production process and above all the alloy.

Further Questions? Talk to an Expert!

Further Questions? Talk to an Expert!