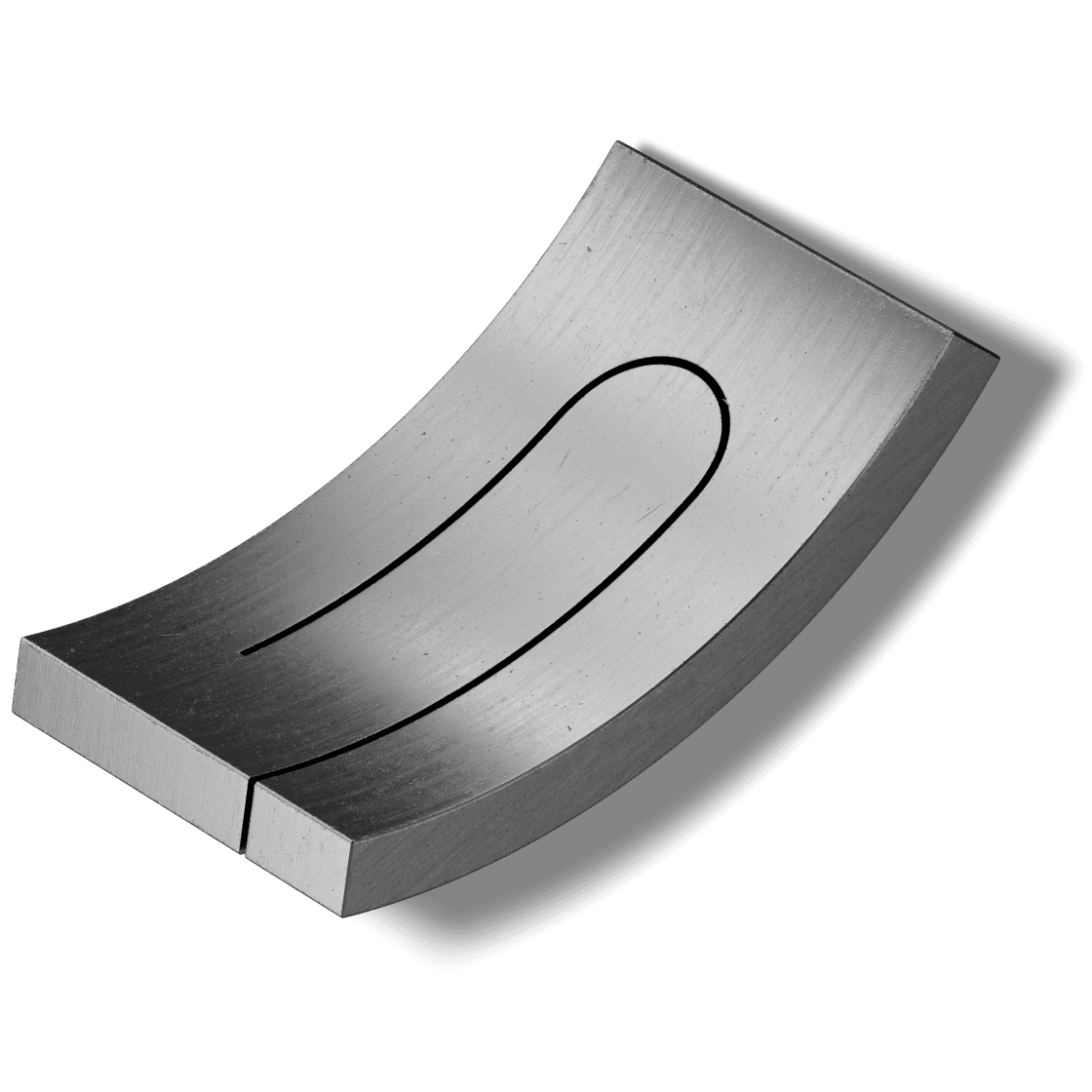

SNAKELINE Eddy Current Reduction

BOMATEC’s innovation

Tackling challenges and solving problems: We understand what our customers need and don’t rest until we find solutions. With our unique SNAKELINE magnets, we’ve achieved an innovation that addresses some of the biggest challenges in high-performance applications: reducing eddy currents, cutting costs, and minimizing environmental impact.

Specifically designed for high-speed and high-performance applications, our SNAKELINE magnets reduce eddy currents through customer-specific segmentation.

RESEARCH AND DEVELOPMENT PARTNERSHIP

Innovation through Collaboration

BOMATEC has been closely collaborating with Flensburg University of Applied Sciences for years. This partnership enables more detailed scientific investigation into eddy current losses in permanent magnets with complex geometries and special measures for loss reduction. The focus of this research includes:

Development of a suitable measuring device to determine the frequency-dependent eddy current losses in sintered permanent magnets made from rare-earth elements.

Development of a calculation and design tool for loss-optimized permanent magnets.

COMPARE PERFORMANCE DATA

3D simulation for your design

Unsure if SNAKELINE magnets are right for your design? We offer comprehensive 3D simulations when needed to easily compare performance data and ensure the best fit for your needs.

SNAKELINE-INNOVATION

Cost-effective, scalable, environmentally friendly

Traditional laminated magnets require extensive labor and often result in unwanted waste. SNAKELINE magnets simplify the manufacturing process and save materials.

The serpentine pattern is precisely wire-eroded into a finished magnet, eliminating conventional steps like cutting, stacking, and gluing individual segments.

his leads to time savings and generates less waste, especially important for price-sensitive and environmentally impactful materials like neodymium or samarium cobalt.

With our range of specially developed epoxy filling methods, we can guarantee the strength required for operation and can rapidly and efficiently implement your custom SNAKELINE magnet design.

Advantages

What’s the benefit for you?

SNAKELINE technology facilitates a cost-optimized manufacturing process and trims down assembly expenses. By adopting a segmented design, we significantly cut down the number of magnets required, streamlining the adhesive process. Our proprietary analysis tool swiftly determines the optimal number and configuration of segments. When necessary, we delve into detailed 3D simulations to fine-tune designs. SNAKELINE magnets offer unparalleled flexibility in shape, allowing for customization of fill factor and mechanical properties to meet your unique specifications.

Talk to an expert!

Taskin Ciddi

Business Development Manager

Magnetic Future Technologies

Innovative solutions for enhanced efficiency

With three decades of expertise and close collaboration with esteemed partners in industry and academia, we've been able to pioneer innovative products and patented processes in the field of magnet technology. Our focus is on delivering peak product performance while keeping costs to a minimum.