Neodymium, Iron, Boron

Hot-pressed

Various magnetization patterns

Product

Powerful, versatile, and cost-effective

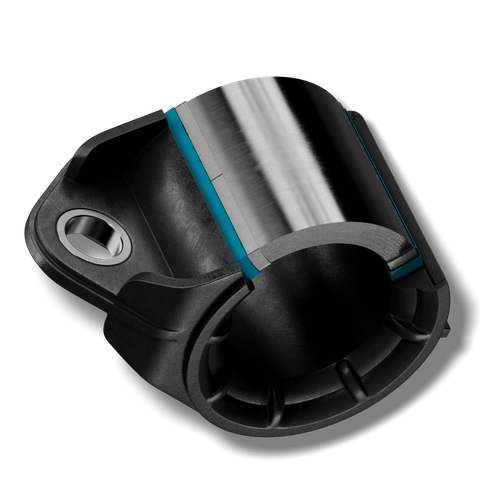

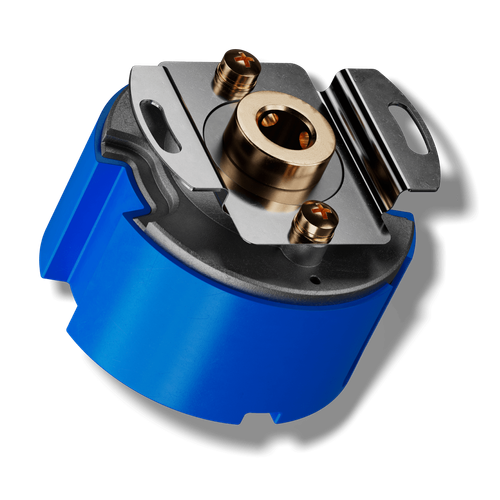

Hot-pressed NdFeB magnets are a special kind of permanent magnet. They are characterized by high performance and precise pole transition, are Dy-free, and are manufactured using the extrusion process. Radial pole alignment is achieved through mechanical deformation. The hot-pressed NdFeB magnet is versatile, suitable for motors with rotor diameters ranging from 6 to 80 mm. It finds applications in a variety of motors, including servo motors, EPS motors, spindle motors, stepping motors, synchronous machines, DC motors, and brushless DC motors. Additionally, it is utilized in sensor applications. By replacing segment magnets and being adhered as a ring onto rotor shafts, it streamlines rotor assembly, making it simpler, more reliable, and cost-effective.

More efficient assembly

Lower tolerances

Inherently better corrosion resistance

General

Setting new standards

Hot-pressed NdFeB magnets are radially oriented, anisotropic, dysprosium-free permanent magnets. They exhibit high coercivity and are among the most powerful magnets on the market. The magnet is available in various sizes of solid rings. The micrograin size of the raw material enables reducing the HRE content and thus lowering costs. Assembly is relatively simple – it consists of a single piece. Compared to sintered, radially oriented ring magnets, very small outer diameters are possible. Hot-pressed NdFeB magnets offer excellent corrosion resistance with minimal internal porosity and are heat-resistant up to 180 degrees Celsius.

Chemical Resistance

Largely Resistant

Motor oil

Organic solvents

Not Resistant

Uric acid

Acids and alkalis

Salts in aqueous solution

Production Process

Hot-pressed NdFeB magnets

Hot-pressed NdFeB magnets are manufactured through a multi-step process, from powder acquisition to cold and hot pressing, to the final extrusion in a hot state. Magnetization is achieved through the thermomechanical process, requiring no magnetic field for production. The magnet shape and size can be determined by the tools used.

Note

While hot-pressed NdFeB magnets boast impressive performance, they do come with drawbacks. Their versatility in shape fabrication is limited, and their production, involving rare earth metals, can be relatively costly. It is wise to explore various magnet options depending on your specific application needs, aiming to minimize any potential extra expenses.

Technical data

What the hot-pressed NdFeB magnet can do

The potential of hot-pressed NdFeB magnets extends beyond standalone applications. These multi-pole magnets are effortlessly integrated into assemblies, offering robust performance without requiring additional protection up to 12k RPM. Their utilization hinges on the magnetization form and the corresponding technical attributes.

NdFeB hot pressed, radial anisotropic

Preview

Further Questions? Talk to an Expert!

Moritz Erdmann

Key Account Manager

MORE THAN JUST MAGNETS

Magnets, Assemblies, Sensors

Performance that delivers

Together we craft success stories

Our commitment is to bespoke product development that meets the highest quality standards and is tailored to the needs of our clients and their applications. It is only through our shared commitment to success and a focus on total customer satisfaction that successful partnership are formed.